AI & Robotics

Transforming Waste Management Through AI and Robotics

At Ken Mills Engineering (KME), we believe the future of waste management is intelligent, efficient, and sustainable. That’s why we’re proud to be working alongside industry leaders Recycleye — pioneers in AI-driven waste sorting — to bring cutting-edge robotic and artificial intelligence technology into materials recovery facilities (MRFs) across the UK and beyond.

Together, we’re reshaping how the world handles waste.

Smarter Sorting, Cleaner Streams

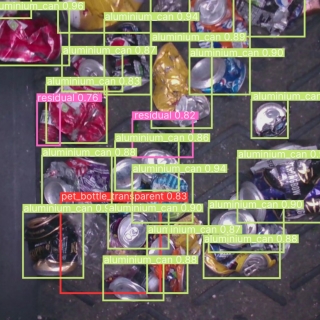

The integration of Recycleye’s AI-powered systems and robotics with KME’s robust engineering solutions brings unrivalled accuracy and efficiency to waste sorting. AI intelligent systems can detect, identify, and sort materials by type, brand, and even object in real time. Whether retrofitting into existing facilities or integrated as part of a new build, our AI + Robotics solution is scalable & adaptable.

Combined with KME’s high-performance conveyors, balers, and turnkey MRF solutions, this partnership enhances:

Material recovery rates

Contamination reduction

Labour efficiency

Overall plant automation

Features

High resolution cameras identify materials by type, color, shape, and even brand.

Capable of recognising plastics, paper, metal, cardboard, and more with high accuracy

High-speed robotic arms sort and extract target materials

AI and robotics can be retrofitted into existing MRF's or integrated into new systems

Reduces dependency on manual sorters for repetitive or hazardous tasks

Compatible with conveyors, optical sorters, shredders, and balers for full plant automation.

Continuous data collection provides live insights into material composition, contamination levels, and sorting efficiency.

Systems learn and improve over time, adapting to changing waste streams and packaging trends.

Why Choose AI-Powered Waste Solutions?

As legislation tightens and demand for clean recyclables grows, MRFs must evolve. The KME–Recycleye solution empowers your facility to:

Automate repetitive, labour-intensive sorting tasks

Adapt to new materials and packaging trends via software updates

Reduce operating costs and improve up time

Deliver consistent, high-purity output

Future-Ready, Today

This partnership signals a step-change in how waste facilities operate — and what they can achieve. Whether you’re upgrading or building new, KME and Recycleye are ready to deliver next-generation systems that meet tomorrow’s standards.

Benefits

Supports safer working conditions and frees human staff for higher-value roles

Enables facilities to meet stricter end-market quality standards.

Contributes to lower landfill rates, reduced contamination, and increased recycling efficiency.

Reduce operating costs and improve up time

Video