Movable strapper for Hay & Straw

13 Mar 2025

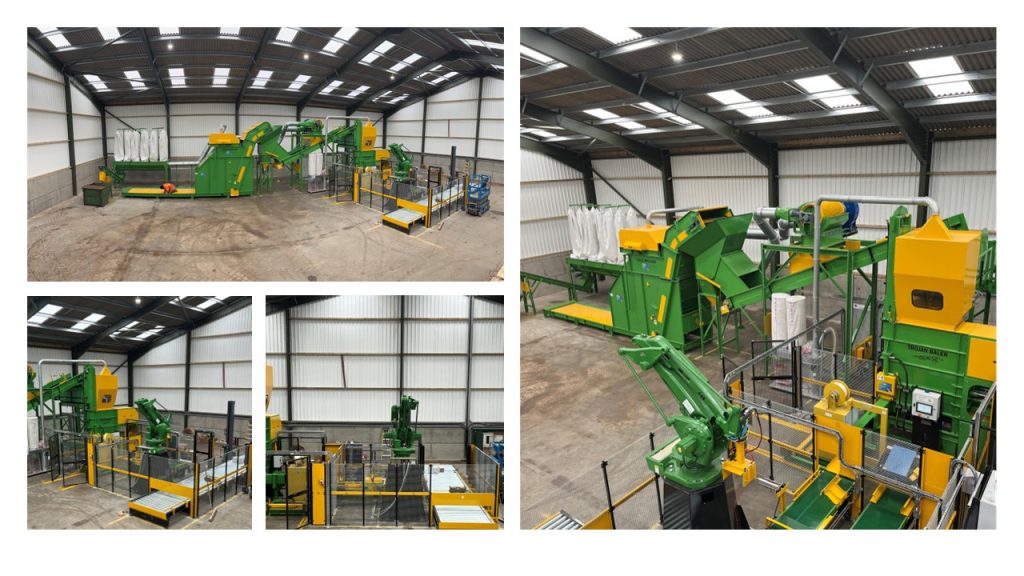

After a fire tore through our customer’s barns, their original KME rebaling system was badly damaged and needed replacing. Fast forward a few months, and we’ve installed a brand-new Trojan rebaling system with a movable strapper unit.

Our customer rebuilt their barn from the ground up to house this impressive setup, which now produces easy-to-handle small bales of hay, straw, and haylage again. Whether strapped or bagged, these bales are perfect for equestrian yards, smallholdings, and pet feed businesses.

Ken Mills Engineering (KME) offer advanced rebaling systems designed to process large bales of hay, haylage, and straw into smaller, more manageable packages. Our systems are equipped with features such as movable bale strappers and bagging options to enhance operational efficiency and product quality.

Key Features:

- Bale Breaking System: The process begins with large round or square bales being placed onto a walking floor capable of holding multiple bales. The bales are then fed into a bale breaker, which gently breaks them down to ensure an even material flow

- Dust Extraction: For materials like straw and hay, the system incorporates a high-efficiency dust extraction drum that removes over 95% of dust and mold spores, resulting in a cleaner product suitable for various applications.

- Weighing and Baling: The processed material is automatically weighed to pre-set specifications (typically around 20 kg) before being fed into the baling machine. The baler compresses the material into compact bales, which are then sealed in plastic bags or strapped.

- Movable Strapper and Bagging Options: KME’s systems offer flexibility in the final packaging, with options for bagging, strapping, or wrapping the bales. The movable strapper ensures secure packaging, maintaining the integrity of the bales during handling and transportation.

Benefits:

- Labor Efficiency: The system is designed for minimal human intervention, allowing for a one-person operation and reducing labor costs.

- High Production Rates: Depending on the material and system configuration, the machinery can produce between 100 to 180 packs per hour, enhancing productivity.

- Product Quality: The integrated dust extraction and gentle handling processes preserve the quality of the forage or bedding material, ensuring a superior end product.