Haylage Rebaling

28 Mar 2024

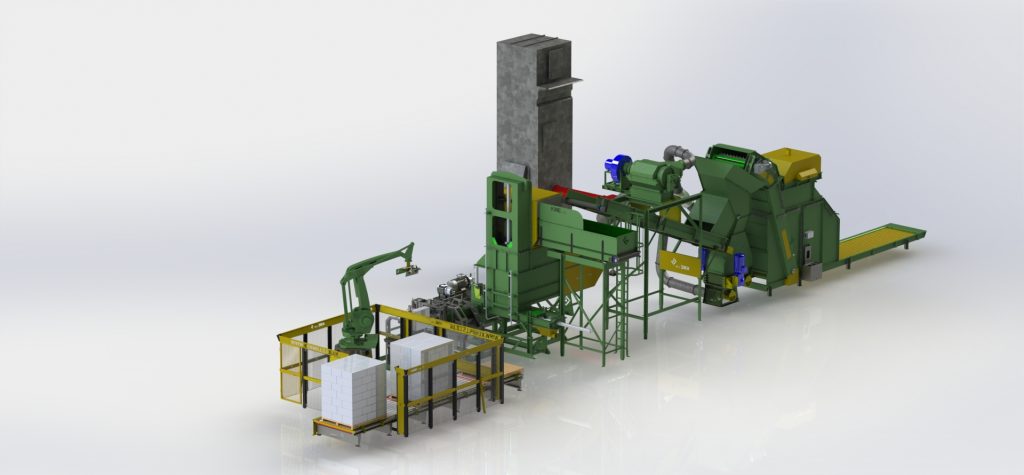

Its been in the pipeline for a long time. The KME team have finally installed our first fully automatic form fill and seal haylage rebaling system.

Bringing our industry leading technology to a new level. Our machines can now process haylage, hay & straw type products with minimal human intervention. This new rebaling finish for haylage will significantly Reduce labour costs, improve productivity without compromising the quality of the product.

How it works :

- Firstly the large square / round bale Haylage will be placed on the walking floor. The walking floor is capable of holding up to 6 off large bales.

- The material then feeds into the bale breaking system where a spiked conveyor and a special ‘Doffing’ system thins the material out suitable for weighing.

- The material feeds onto the weigh conveyor where the system automatically weighs out approx. 20kg/ 45lbs of the loose material.

- Once the weight is achieved the weigh conveyor automatically feeds the weighed material direct into the packing unit.

- Then the packing unit compresses the material down into the finished size packs – direct into a plastic bag with nominal measurements of 600 x 400 x 220mm.

- The bag is then automatically sealed using a special twin seal heat sealing unit.

- Capacity of the system is up to Max. 140 x packs per hour.

Benefits of using our machinery :

Reduces labour costs, one man operation (robots have minimal days off sick!)

Generate larger incomes for your farm

No compromises on haylage quality rebaling to small

Make large bales in the field for speed & beat the weather – rebale at your leisure

Branding your bags increases reach of your product

20kg packs are convenient for horse owners without machinery / limited storage / few horses / transporting

Easy to stack & transport to stockists or deliver direct to customers