KME Secures Major UK MRF Retrofit

23 Oct 2025

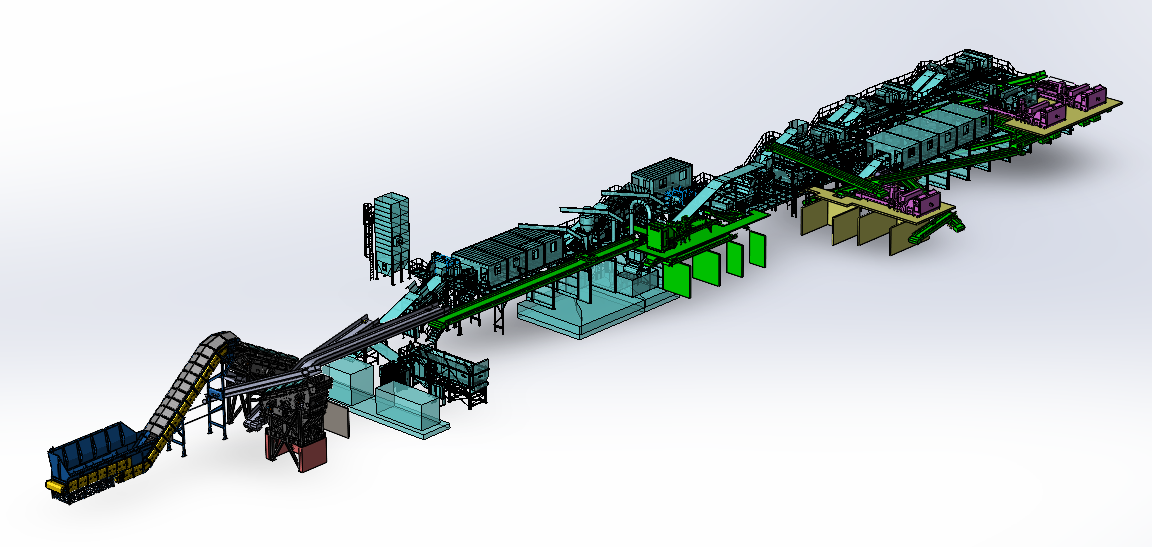

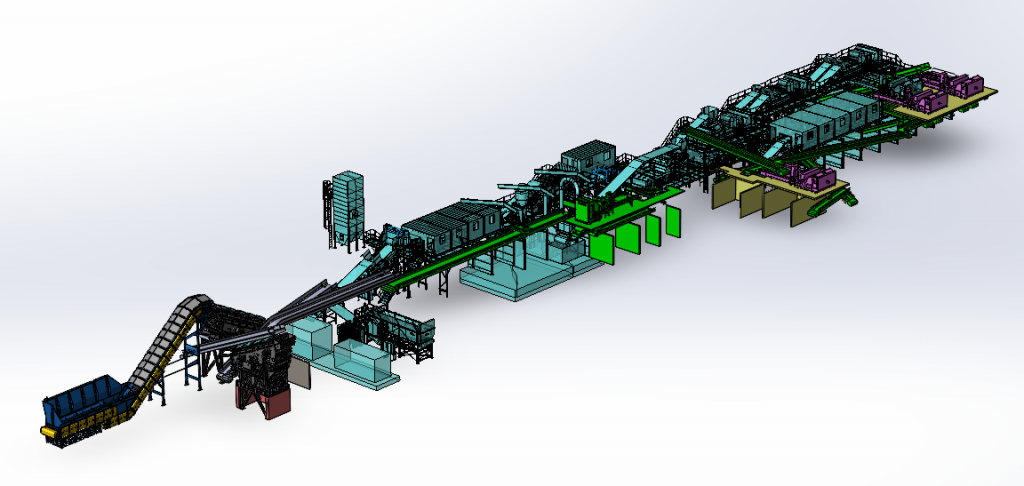

We’re excited to announce that KME has secured a major UK MRF retrofit project. This upgrade will modernise an existing recycling facility. We are partnering with Recycleye and Blue Machinery Scotland to bring next-generation automation and AI-driven sorting technology to the plant.

27 Conveyors in Manufacture

The project includes 27 new conveyors now in manufacture. These conveyors will improve material flow and overall efficiency. The infeed system is also being upgraded. It will handle larger waste items and flexible film more effectively.

A key feature of the retrofit is the AI-powered aluminium sort line. It uses Recycleye’s optical sorting technology for better quality control and detailed data capture. Additionally, the scavenger line has been enhanced with an eddy current system. This will recover any missed aluminium and maximize material recovery rates.

Post-sort operations will benefit from advanced optical sorting as well. This improvement will enhance material quality and provide more accurate operational data. These automation upgrades will reduce manpower requirements while boosting throughput and efficiency across the sort line.

This UK MRF retrofit upgrade shows how modern recycling facilities adopt automation and AI to meet growing recycling demands. It will improve recovery rates and optimize operational performance. By investing in next-generation sorting solutions, the facility sets a new standard for efficiency and sustainability.

Well done to everyone at KME, Recycleye, and Blue Machinery Scotland for making this project a reality. It’s inspiring to see UK recycling facilities embracing innovative technology to deliver smarter, cleaner, and more efficient operations.