Wood Wool dust & contaminant removal

10 Aug 2020

Another brand new use for KME ltd machinery

Over the years KME Ltd have been approached by many product manufacturers. Asking if our machinery can be adapted to suit their requirements. Earlier this year Andy Mills, Managing Director of KME ltd met with a company producing wood wool. This is a very versatile product which has been around for many years. Its uses are eco-friendly packaging, animal bedding, natural firelighters, acoustic boarding and much more.

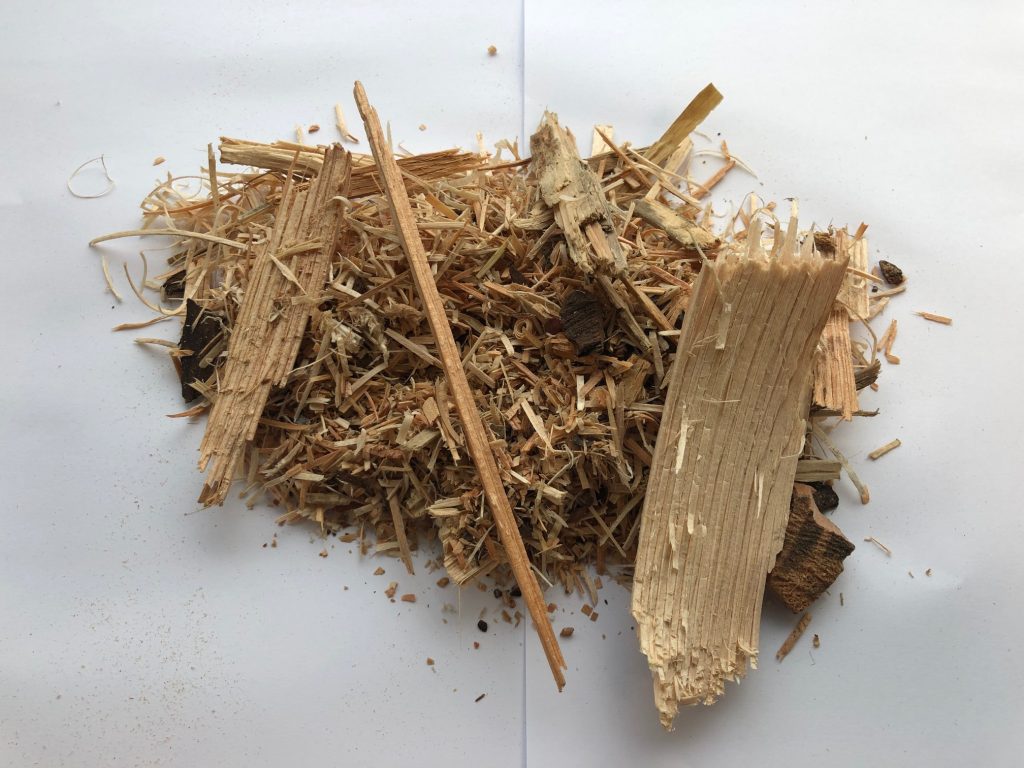

The process of making wood wool is simple. The wood is firstly harvested and logged. The logs are then stripped of their bark and cut to small manageable lengths. These lengths are placed onto the wood wool machine, which cuts the wood into ribbons that resemble wool. The removal of larger contaminants such as bark, large splinters and fines was the customers main requirement.

The larger pieces were hand picked from the wool, which was a tedious job and not always 100% efficient. The lighter dust was removed when the wool passes over a perforated conveyor. Again wasn’t the most effective method for collection or removal of the dust.

Fine dust Contaminants

Heavy contaminants

Original system setup

How we helped..

To update and solve the issues with their existing process, we integrated our unique delivery drum / dust removal system. The wood wool cutting machinery now feeds the cut ribbons onto a new conveyor, transferring the product and waste items to the suction hood of the KME delivery drum. Heavies fall off the end of the conveyor and the lighter ribbons and dust are pulled up into the drum. The filter system collects the separated dust.

After the above process is complete the wood wool is clean from any contaminants, another benefit is that the environment is now cleaner for employees to work in. Collection of these by-products allows them to be reused. They fuel the heating system for drying out the logs earlier in the process.

KMEs Ltd delivery drum systems can be integrated into many different product processes. Such as – Animal bedding (shavings, card, hemp, straw) carpet fibres, wood recycling, textiles, straw, hay etc